Choosing the Right Torq-set Bits for Your Tool Kit

Share

Finding the right tools for your toolkit can be a challenge, especially when it comes to specialized components like Torq-set bits. Whether you’re a DIY enthusiast or a professional mechanic, understanding the specific applications and benefits of these bits can greatly enhance your efficiency and precision.

Understanding Torq-set Bits

Torq-set bits are uniquely designed for aerospace applications, but they have found their way into various professional toolkits due to their precision and reliability. Understanding their specialized design can help you decide when and where to use them effectively.

The hallmark of Torq-set bits lies in their distinct cross shape with unequal arms, which differentiates them from other more common bit designs. This configuration allows for high torque transfer, reducing the chances of slippage and improving grip on fasteners. This is particularly useful in scenarios where reliability is critical, think of assembly lines in the aerospace industry, where the margin for error is virtually nonexistent. Learning to appreciate the design and function of these tools can make your work not only easier but also more accurate.

Torq-set bits are versatile and can be integrated for more than just aerospace use. They are an excellent choice for any work demanding precision, such as in electronics assembly or when dealing with delicate mechanical components. Incorporating these into your toolkit means you’re prepared for intricate tasks where a slip-up could be costly.

Different Types of Torq-set Bits

Torq-set bits come in various sizes and configurations. Knowing the range of types available, from standard to customized options, can help you choose the best fit for your specific tasks and projects.

The world of Torq-set bits is diverse. Typical types range from mini-sized bits designed for fine detail work, to larger, more robust bits meant for heavier tasks. For instance, smaller sizes can be ideal for delicate tasks like adjusting electronic devices or assembling drones. In contrast, larger bits are more appropriate for robust jobs like automotive assembly. Recognizing the scope of Torq-set options is crucial, as it allows you to tailor your toolkit to your needs, ensuring that you are not caught off guard without the correct tool.

Customization plays a significant role in the selection of Torq-set bits. With options available for length, material, and coating, you can select bits that cater precisely to the environmental and operational demands of your projects. For example, coated bits might be essential in environments prone to corrosion or in applications requiring extended durability. By evaluating these options carefully, you can optimize your toolkit for both performance and longevity, giving you a clear edge in your work.

Benefits of Using Torq-set Bits

These bits offer several advantages, including enhanced grip and control, leading to fewer cam-out occurrences. This section will explore why they are preferred in critical applications where precision is key.

One of the standout advantages of Torq-set bits is their ability to maintain a snug fit within the screw head. This reduces the tendency for the bit to ‘cam-out’ or slip, which is a common issue with more traditional bit designs. A reduced cam-out rate not only preserves the integrity of the screw but also minimizes wear on the bit itself. This is especially beneficial in high-stress environments where each fastener must be secure for safety and functionality.

Furthermore, Torq-set bits offer increased efficiency through their superior torque transfer capabilities. Their design allows for greater rotational force to be applied directly to the fastener, meaning less effort is required from the user to achieve the same level of tightness. This efficiency is invaluable in manufacturing and assembly-line settings, where every second counts and operator fatigue must be minimized to maintain productivity levels.

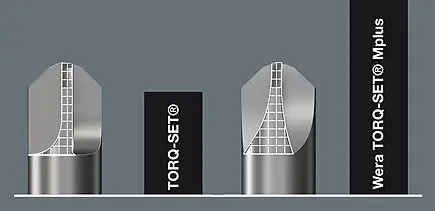

Torq-set Bits Offered at Palmac Tools

At Palmac Tools, we’re proud to offer a wide selection of Torq-set bits, including Wera Torq-Set® Mplus bits, trusted worldwide for their unmatched quality and precision. Wera’s Torq-Set bits are specifically designed for Torq-Set fasteners, featuring the distinctive offset cruciform pattern commonly used in aerospace, defense, and other mission-critical industries. Engineered from Wera’s premium tool steel and enhanced through advanced heat-treatment processes, these bits deliver exceptional durability, reduced wear, and a secure fit that minimizes cam-out even under high torque loads. Available in a broad range of sizes and lengths, they’re perfectly suited for both manual tools and power drivers, ensuring reliable performance in the most demanding professional environments.

Click here to view and purchase Wera 871⁄4 TORQ-SET® Mplus bits